MHK Automatic hot foil stamping and die cutting machine

- Model

- MHK-1050T /1050TC

Review

Description

(1) Adopt nodular castiron-QT500-7, the mainframe wallboard casting by special technology process,thus featuring

by high strength, never deformation and ensure the safety of themainframe wallboard.

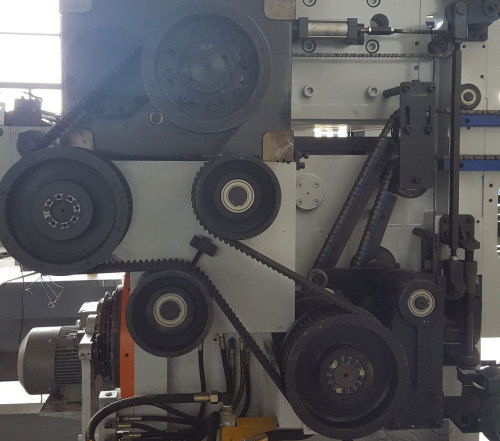

(2) AdoptTaiwan-imported intermittent mechanism to ensure that the machine operatesaccurately. Also, the main

engine is equipped with overload protection deviceand torque limit clutch,to ensure that when they being impacted

by externalforce can stops immediately to reduce the damage to the machine body and teethprecision and reduce

the occurrence of failure rate.

(3) The whole machineall uses SKF\NSK imported original bearing.

(4) The whole machineuses original parts imported from France Schneider,Japanese OMRON, and Japanese

Mitsubishi etc.

(5) Key parts of teethrow are imported from Japan.

(6) Die cutting and hotfoil stamping accuracy reach to ±0.1mm, and the highest speed of machine reaches

7500sheets/hours.

(7) The craft shaft isadopts Germany Ni-Cr-Mo metal steel, with high precision and will neverdeforms.

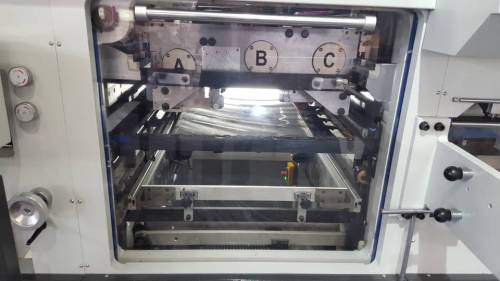

(8) Use the centerlinepositioning system to realize fast plate changing of worksheet.

(9) Equiped first-developed pressure servo control device,ensure fast and smooth when they adjusting of die

cutting pressure.

(10) Equip withtouch-screen operation interface in both Chinese and English.

(11) All adopt TaiwanAIRTAC pneumatic components to ensure every pneumatic action performsaccurately.

(12) Adopt double-sheetdetector.

(13) The papercollection platform machine is equipped with automatic auxiliary papercollecting mechanism

and operate without stopping the machine.

(14) The side gaugeadopts photoelectric system.

(15) Adopt automaticrefueling system.

(16) The oil pumpadopts automatic cooling fan device.

| Model | MHK-1050/ MHK-1050CE |

| Max.paper size | 1050*750mm |

| Min.paper size | 400*360mm |

| Max die cutting size | 1040*720mm |

| Gripper | 9-17mm |

| Size of inside plate frame | 1080*745mm |

| Cardboard thickness range | 80-600 gsm (cardboard) Less than 4mm (corrugated board) |

| Die cutting precision | +-0.1MM |

| Max working pressure | 300T |

| Max.die cutting speed | 7500sheet/hour |

| Max paper feeding stacking height | 1600mm include pallet |

| Max paper collection stacking height | 1400mm include pallet |

| Main motor power | 11KW |

| Machine size | 7700*4600*2400mm |

| Machine weight | 17Ton |

| Full-load power | 16.9 KW |